Ask an engineer, architect or developer about the future of building, and it won’t be long before you hear three letters – CLT. But what is CLT? And why is it all the talk in industry circles?

CLT, or cross-laminated timber, is an engineered wood product made by gluing layers of dimension lumber at orthogonal angles to one another. You can build CLT panels to be anywhere from 3 to 9 plies thick, and spans can be as long as 60 feet. All these dimensions vary by manufacturer, but there are certain standards that the CLT panel has to meet. These tolerances are spelled out in PRG 320, which is a joint Canadian and American product standard published in 2012.

Cross-laminated timber has been used since the early 90s in Europe, in countries like Austria and Germany, and in recent years has been gaining popularity in Canada. Since 2005, organizations like FPInnovations, a private scientific research center based out of Vancouver, B.C., have been researching the potential CLT has to offer the construction world. The United States recently joined the CLT conversation, and PRG 320 was published to allow engineers to start to design with it. A chapter has been added for CLT in the newest NDS for wood construction, with reference design values, adjustment factors and special design consideration sections included.

The Need for CLT

So why the push for CLT now? A green, renewable construction material is needed now more than ever as our cities continue to grow and climate change continues to be a serious concern.

A feasibility study was done by architect Michael Green, in collaboration with the Canadian Wood Council, to illustrate how “massive timber products can provide viable and sustainable alternatives for construction of 10 to 30 story buildings.”

Architects and engineers alike are excited about the prospect of having a product that offers comparable strength and price points to a concrete-steel structural system, all while being a greener, more renewable resource. Mills would have a new market to provide for, design firms would have greater variety for wood projects and contractors would benefit from the decreased construction time and increased ease of installation.

Advantages of CLT

1. Green/renewable

Green and other industry leaders hope that mid-rise wood construction will become the norm in the very near future. Globally, deforestation is a significant contribution to greenhouse gases (10%), but sustainable forestry methods are now the standard in Canada and the United States. The use of CLT could still help promote healthy forest management and potentially help revitalize the economies of rural communities that have been hit hard by the decline of the timber industry. CLT can be made from smaller, younger trees than dimensional lumber requires, and the industry is studying whether CLT could be made from beetle-kill wood, which is otherwise emitting carbon into the atmosphere as it decomposes. British Columbia alone has 44 million acres of beetle-infested trees.

2. Carbon sequestering

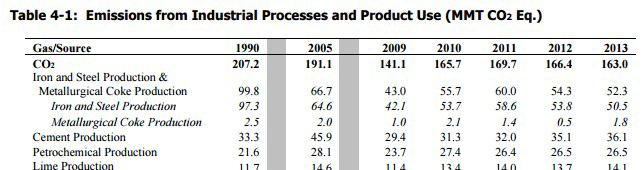

Currently, steel accounts for about 7% of our nation’s greenhouse gas emissions, while concrete accounts for about 5%. As shown in the Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2013 - Industrial Processes and Product Use, iron, steel and cement production contribute the most of any industrial process to CO2 emissions:

There are two solutions to climate change: reduce our emissions and/or find storage (a.k.a. carbon sequestering). Wood is the only building material on earth that simultaneously does both of those things. For so long, steel and concrete have dominated the mid to high-rise construction sector, but with the arrival of CLT this could all change. Building with a product that not only produces less carbon dioxide but actually sequesters it is an immediate step in the right direction for the building industry towards reducing the impact construction has on global climate change.

3. Ease of Construction

One of the major advantages with using CLT in buildings is ease of construction. The panels arrive on the job site pre-fabricated and ready to install. Installing them is a quick process for the contractor. With this being a major advantage, it is important to make sure the construction process isn’t slowed down by the installation of complex connections. A complicated connection could be designed that behaves the way it needs to, but if it takes a long time and is meticulous to install, requiring engineer supervision or other materials, then it defeats one of the reasons for using CLT in the first place.

4. Strength Properties

Another major advantage is the relatively high in-plane and out-of-plane strength and stiffness in both directions. CLT panels have been shown to behave with similar capabilities as a reinforced concrete slab. (Mohammad, 2012). Similar strengths can be achieved using much less weight, as CLT is much lighter than concrete or steel.

Challenges

Despite CLT’s promising qualities, most building codes still require that CLT be designed under the Alternative Means and Methods section of the code, requiring more design work and site-by-site decision. The two biggest obstacles to getting CLT into our code are the seismic design and fire safety requirements. A response modification factor is still needed for CLT, and research is being done currently to try and determine this.

Fire Rating

Because US fire codes are more restrictive than European codes, implementing CLT into the high-rise construction has been a harder process. Extensive testing has been done to address this issue, and it has been shown that CLT behaves similar to the IBC Type IV Heavy Timber fire rating. Tests have shown that CLT chars in a slow and predictable manner, and when used as a fire-wall you can get up to a 2-hour fire rating. In the updated 2015 NDS, a modified char rate equation has been included so that designers can show that they can achieve an adequate fire-wall rating for their building.

Seismic Design

Seismic design is one of the biggest barriers when it comes to integrating CLT into the building code. CLT is stiff, meaning that ductility must be achieved through the connections. Canadian Lumber Council tests have shown that CLT wall panels can be used as an effective lateral load resisting system. Shake table tests showed that CLT wall panels demonstrated adequate seismic performance when nails or slender screws were used with steel brackets to connect the wall system to the flooring system. When the earthquakes were simulated, ductile failure occurred in the connections, though brittle failure did not occur in the panels themselves. Mohammad suggests using half-lapped joints in longer walls to lower the walls stiffness, and thus, reduce the seismic load input.

The SOFIE project in Italy performed a series of tests on connections in single-story buildings under a simulated earthquake. They were also able to build a 7-story building on a shake table to simulate different levels of earthquakes intensities. The quasi-static tests yielded that “the connection layout and design had strong influence on the overall behavior of the wall.” They found that 12% damping could be achieved, which meets the requirements for high seismic zones like Seattle. The SOFIE tests further confirmed that the behavior of the wall is governed by the connections, and not the wood panels themselves, for lateral resistance at the lower levels.

While tests like this are moving the conversation forward as far as seismic design, more testing is required to show that adequate ductility can be achieved in high seismic regions like Seattle and Portland. Steel and concrete are still the most common materials for mid-to-high-rise construction, but CLT could begin to make more sense as its seismic qualities are tested and proven further.

Jon Potter was recently hired as a Project Engineer in DCI's Seattle office after starting with the company as an intern in 2015. He graduated from Washington State University with a Bachelor's degree in Civil Engineering and is currently pursuing his Master's degree. He has a passion for mass timber and other emerging technologies in wood construction.